|

Page 2 -

Hard Core on the Milford Road Course

It’s the afternoon of June 4th, 2004 at GM’s enormous Milford Proving Ground 35

miles northwest of Detroit. I had just track-tested the C6 for the first time.

“OH YEAH”! I stood, pulling my helmet off, about 10 yards downwind of a

spanking-new Machine Silver 2005 Z51 six-speed. I heard the exhaust tickety-tick

as it cooled. I smelled brake pads. I nodded, smiled and thought…this is one

hard-core killer ride!

GM has a new facility at the Grounds called “MRC” (Milford Road Course). It's a

Bob Lutz initiated, mini-Nurburbring, designed by GM engineers Mike Neal, Joe

Ryan and Jim Mero and built during the '03-'04 period. It's 2.9 miles, 20 turns

and a 135-ft. in elevation change. At the end of its longest straight, Corvettes

are at the top of fourth gear, a little short of 150 mph. It's got about every

performance driving challenge you'd expect in chassis engineer heaven. MRC's

most demanding aspect is that every corner has both lateral and vertical

accelerations, so when you turn; you get heaved up or slammed down, too. Sound

like fun? It is! I had five laps in that silver C6 about as fast as I could go

on sections of MRC I'd learned in the short time I was there, and as I said: the

'05 Z51 is pretty impressive.

I looked at an '04 Z06/Z16 GM had parked nearby for comparison (interestingly it

was 00025, sister to my own 00039, which I'd driven just before catching a jet

to Michigan), and thought of what Mike Neal, who, in addition to designing test

tracks tunes Corvette's ride-and-handling, told me "The huge thing with the

new Z51 is handling! I mean, you are not all the way to a Z06; but you're darn

close." I totally agree–and I'm not the only media wonk who does so. Most

who have tested it–except maybe those silly Brits who do the U.K.'s "Top Gear"

TV show–have been impressed with C6's performance.

What's an '05 like on the track? Corner entry is more refined. Going in a C5 was

good but, sometimes just a tiny bit on the oversteer side, so it was never easy

to trail brake. Also, if the road was rough, because that would put the front

end on the bump stops occasionally, the car was a little nervous.

|

|

This is the Silver Z51 I tested on the MRC. You can see a lot here. Hard on the brakes, going into this turn at the MRC, the car is not tail-out at all. Look how the outside wheels plant that contact patch square on the road.

Image: Author. |

|

C6, especially under braking, is more tail-in. Plus, on a rough or undulating surface, it's less likely to touch the jounce bumpers and that keeps the front end planted more securely. Better manners going into a turn has the driver not working as hard and–smooth is fast. This more settled behavior comes from increased ride travel with shock valving to match, vastly improved Goodyear EMTs and increased limited-slip differential pre-load.

In the midpoint of a turn, because of increased grip from the new run-flats and more roll stiffness from bigger antiroll

bars; the car's lateral acceleration increases. Even base cars do 0.92g.

. |

Plus, as you're more stable transitioning from corner entry,

you're not having to calm a slightly iffy car near the apex. In turns with dips

or bumps, extra travel and changes in shock valving have the car more poised,

so, even at the limit; it rides better.

Off turns, C6 gets its additional torque and horsepower down well. The key enabler of that is, again, increased travel, revised shock valving and more compliant tires. Also, helping is stability earlier in the turn, ie: if you come in a little less tail-out and do the apex with more finesse; that smoothness carries into the exit, giving you a faster speed out.

The 2005 Corvette's at-limit-handing improves and is more easy to manage. Not only is the new Z51 almost as good as the '04 Z06, but base C6es are quicker around many tracks than were C5 Z51s. No matter which '05 you drive, you look better and are more comfortable while being just that little bit quicker.

Suspension and Brake Hardware

"Everything with the C6 starts with the C5," Mike Neal told us. "We asked, 'Ok. What do we like? What could we improve on? What takes an architecture change to improve something we couldn't on C5?' We wanted to improve ride. We wanted to decrease noise. We wanted to improve handling."

|

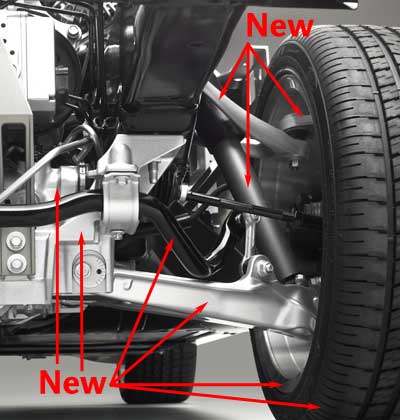

To do all that required redesigning the suspension. At first the parts seem the same, but look close; and you see nothing carries-over. In the front, the suspension cross member, steering rack, control arms, antiroll bar, shocks and knuckles are new. This was to increase the front ride travel, add one degree caster to reduce "trough-wander" and to stiffen the knuckle for less deflection under heavy braking.

In the rear, the cross member, control arms, antiroll bar, spring, shocks and knuckles were redesigned. This was to increase ride travel, allow relocation of the spring above the control arms, allow a second transaxle mount to improve damping of powertrain movement and to stiffen the knuckles for less deflection under braking.

Brake pieces are new, too. Brakes were a C5 problem, especially

in the first couple of years |

|

Worm's eye view of the C6 front suspension. Just about everything is new.

Image: GM Communications. |

|

when brake shudder due to rotor thickness variation was

somewhat common. C5 ended its

run with its highest warranty cost, on a proportionate basis,

being brakes. GM wanted to continue to improve that area on the '05.

|

|

|

A lot has changed with the brakes on the new car. With the base brakes, shown here, the result is better rotor durability and less noise. Image: Richard Price. |

|

The base brake rotors have more mass, a revised hat section, thicker brake plates (the part of the rotor swept by the pads) and different venting. All this was done to reduce thickness variation due to heat cycling and to eliminate brake noise. Brake calipers are still aluminum, but otherwise are a new design which is stiffer across the bridge, has a lower parts count and less brake drag.

One big contribution to C6's improved ride and handling are the new, third generation, Goodyear EMTs. So far, there are two: the Eagle F1 GS-2 EMT, for base and F55 cars, and the Eagle F1 Supercar EMT on Z51s.

The 3rd gen. run-flat tire construction is vastly different. The tire casing is more compliant, made possible because of a decrease in the GM specification for run flat distance from 200 to 100 miles, and is made with lightweight materials in sidewall areas which supply the support structure when the tire has low or no air pressure. The additional compliance, along with new: mold shape, tread compounds and tread patterns, all enhance the tire contact patch when it's loaded in a turn. |

|