|

For

Release: Jan. 1, 2004, 12:01 a.m.

2005 CORVETTE ENGINE: MOST STANDARD

POWER EVER

DETROIT - GM today announced the new 2005

Corvette will feature the most powerful standard engine ever in

Corvette history: the 400 horsepower, 6.0-liter, small-block V-8.

The new 6.0-liter LS2 is part of the fourth generation of GM’s

small-block engines. The small-block debuted in 1955 with 265 cubic

inches and 195 horsepower. Since then, this legendary family of

engines has been an integral component of Corvette’s performance

history.

“It’s almost impossible to talk about Corvette without the

small-block,” said Dave Muscaro, GM Powertrain’s assistant chief

engineer of small-blocks for cars. “As Corvette has grown into a

world-class sports car, the small-block has grown with it. The LS2

is a state-of-the-art engine that draws on a rich heritage of

performance.” Powertrain’s assistant chief

engineer of small-blocks for cars. “As Corvette has grown into a

world-class sports car, the small-block has grown with it. The LS2

is a state-of-the-art engine that draws on a rich heritage of

performance.”

The LS2 also raises the bar for standard performance in the

Corvette, delivering 400 horsepower at 6000 rpm and 400 lb.-ft. of

torque at 4400 rpm – an increase of 50 horses and 40 lb.-ft. of

torque over the previous Corvette’s LS1 engine.

“More than dynamometer numbers, the LS2 engine’s range of power

and torque is broad and very usable in everyday driving,” said

Muscaro. “This engine is smoother, and more refined, but at the same

time retains tire-thrashing output.”

Design changes for the better

Compared to the

Gen III-based LS1, the LS2 incorporates several significant changes

that help improve performance, reliability and serviceability:

-

All-new aluminum block casting incorporates provisions for

external knock sensors and revised oil galleries; external sensors

improve serviceability

-

Cylinder bore diameter increased to 101.6 mm (4.00 inches),

increasing displacement to 6.0 liters

-

Camshaft lift increased to take advantage of increased

cylinder head flow

-

Camshaft sensor relocated from the rear of the block to the

front of the block provides room for new oil galleries

-

Flat-top piston design with lower ring tension reduces

friction

-

Piston floating wrist pins help quiet the engine

-

Redesigned, “wingless” oil pan with cast baffling has reduced

mass and provides superior oil control under high-performance

driving maneuvers

-

Revised exhaust manifolds are 33 percent lighter

-

More efficient ignition coils require less energy to provide a

comparable spark

-

Compression raised to 10.9:1

-

Larger, 90-mm single-blade throttle body

-

Reduced-mass water pump design with improved sealing

capability

-

Engine “redline” raised to 6500 rpm

-

Revised and more powerful engine controller incorporates all

electronic throttle control functions.

-

Mass has been reduced by 7 kilograms on the automatic version.

Cylinder heads for the LS2 are derived from designs used in

previous Corvette Z06 models, including raised intake ports and an

unshrouded-valve combustion chamber design that, when combined with

the engine’s flat-top pistons, produces a more efficient swirl of

the air/fuel mixture. This efficiency enables a higher 10.9:1

compression ratio, which increases fuel economy and horsepower.

Valves measure 2 inches for the intake and 1.55 inches for the

exhaust. The valve springs also have been upgraded to withstand the

engine’s increased power and rpm range.

The LS2’s new oil pan was developed to ensure oil delivery

commensurate with Corvette’s high-performance capability. Extensive

track testing has shown the new design to provide better oil control

under the extreme demands of high-rpm/high g-force driving

maneuvers. The elimination of the previous “gull wing” oil pan

design also reduces the engine’s oil capacity from 6.5 quarts to 5.5

quarts with a dry filter.

Engineers also increased the efficiency and reduced the mass of

the exhaust manifolds. Wall thickness of the manifolds is reduced

from 4 mm to 3 mm, eliminating weight and helping enhance airflow by

approximately 4 percent.

“We sweated the details to ensure the engine maintains a balance

between performance and efficiency,” Muscaro said.

Several of the new features of the LS2 were incorporated as

continuous improvements to later versions of the Gen III engine,

including long-life, iridium-tip spark plugs; pistons with full

floating wrist pins; a redesigned water pump that significantly

reduces the probability of a leak; and a stronger, long-life timing

chain.

Building on a proven foundation

The LS2’s Gen

IV architectural roots lie in the proven LS1 5.7-liter Gen III V-8

that was standard in the Corvette C5. It was an engine that

redefined performance and efficiency expectations of cam-in-block

architecture.

Like the venerable small-block engine introduced in 1955, the

modern small-block features a 90-degree cylinder bank arrangement

and 4.40-inch bore centers – the distance between the center of one

cylinder and the center of the next. The Gen IV builds upon the

strengths of the Gen III small-block architecture, including:

Aluminum block with iron cylinder bore liners: The lightweight

block is cast from 319-T5 aluminum with cast-in-place iron cylinder

bore liners. A die-cast aluminum valley cover and upper deck rails

tie together the cylinder banks, increasing torsional and bending

stiffness.

Deep skirt block: Structural rigidity and operating smoothness is

enhanced because the engine block extends below the crankshaft

centerline.

Cross-bolted main caps: Two horizontal cross bolts for each main

bearing cap complement four traditional vertical main cap bolts and

contribute additional strength and smoothness to the engine’s

rotating assembly.

Gerotor oil pump: Simple and compact in design, the gerotor-style

oil pump fits the shallow oil pan and offers superior pumping

capability.

Balanced cylinder head design: Performance and efficiency is

enhanced with identical airflow and energy direction for each

cylinder.

Coil-near-plug ignition: A separate ignition coil pack and short

spark plug wire for each cylinder maximize the efficiency of the

delivered coil energy, enhancing fuel efficiency and power.

Electronic throttle control (ETC): Instead of a mechanical

linkage between the gas pedal and engine throttle, an electronic

throttle control system improves driveability and reduces overall

system complexity by eliminating typical conventional mechanical

items, such as the idle air control motor, cruise control module and

throttle relaxer (traction control).

Because the LS2’s new engine controller incorporates ETC

commands, the separate ETC module used on the LS1 is no longer

required. This allows faster communication of the controller to the

throttle, as well as reducing the mass and complexity of the system.

Additionally, emissions are slightly improved with the damping of

unnecessary throttle movement.

Improvements to the engine’s crankcase breathing and ventilation

were made similar to the LS6 engine, including moving the crankcase

ventilation system’s PCV valve away from the rocker covers and into

the block valley.

“The small-block V-8 is a powerful and continually refined

package that stacks up with the best engines around the globe,” said

Muscaro. “The Corvette is simply the best way to showcase its

world-class traits.”

Exhaustive efforts Exhaustive efforts

Advances in catalyst

substrates made possible catalytic converters that are at the same

time more effective and less restrictive for the LS2’s exhaust. The

new converters are mounted closer to the exhaust manifold for

quicker lightoff and reduced cold-start emissions. As a result, the

more restrictive quad catalyst design of the LS1 – with its small,

auxiliary “pup” converters – was not necessary to meet emissions

requirements. An additional benefit of the exhaust system’s

development was the elimination of the LS1’s air injection reaction

system.

Subtle adjustments were made to the Corvette exhaust system

itself to improve its performance. Sharp angles in the tubing have

been replaced with more gradual bends. A larger muffler volume and

tri-flow technology eliminated certain periods prone to unwanted

noise, particularly between 1500 and 2400 rpm. An inline muffler

that flows more efficiently replaces the laterally mounted muffler

in the C5. These changes, coupled with one converter per exhaust

bank, reduced backpressure in the system and contributed to the

LS6’s 400 horsepower and 400 lb.-ft. of torque.

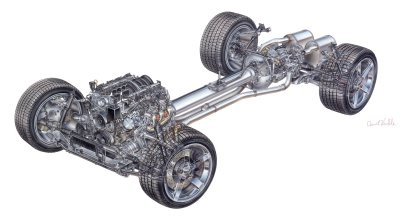

Changing gears

The 2005 Corvette continues to

offer drivers thrilling driving dynamics, whether they prefer

shifting or leaving it to the transmission. The Tremec T56 six-speed

manual is standard and the Hydra-Matic 4L65-E four-speed automatic

is optional.

Corvette engineers thoroughly revised the Tremec gear box and

added proprietary technology not offered on other automakers’

high-performance transmissions. The six-speed transmission also has

revised gearing when selected with the Z51 performance option. With

the Z51, the Tremec is tailored with numerically higher gears to

improve acceleration. Also, a lower fifth gear gives the Z51 better

fuel efficiency and a higher top speed than base models. To increase

durability in sustained high-speed situations, the Z51 and the base

European manual-transmission models have a transmission cooler.

Smoother shifting six-speed

2005 Corvette

drivers will find more pleasing, performance-oriented shifts with

the six-speed transmission. They’re smoother and more precise, with

shorter overall throws. The gear shift lever is now an inch shorter,

and travel for all synchronizers is reduced by 10 percent. An

all-new shift linkage and shift-rail bearings contribute to a more

positive, confident feel. Computer Aided Gear Selection (CAGS)

continues as a fuel-economy enhancement function for the manual

transmission.

Durable 4L65-E delivers automatic

performance

The available automatic transmission in the

Corvette is the new Hydra-Matic 4L65-E four-speed. An upgraded

version of the C5’s 4L60-E, the “L65” is strengthened and revised to

accommodate the LS2’s 400 lb.-ft. of torque.

To beef up the internals, a five-pinion planetary gear set was

added – replacing a four-pinion gear set. The extra gear reduces

friction and loads carried by all the gears. The washers between the

gear sets are made from Teflon, allowing optimal operation at high

speed.

For protection from the high temperatures that are generated by

high speed, a four-plate oil cooler has been added. When the

transmission fluid reaches 127 degrees Celsius (approximately 260

F), the torque converter lock does not disengage, except briefly

during shifts. This prevents fluid shear in the torque converter

from adding heat to the transmission.

The 4L65-E uses a highly advanced electronic controller that has

been specifically calibrated for Performance Algorithm Shifting.

This technology automatically selects the optimal gear for a given

driving condition, making it a willing accomplice for performance

driving and hard cornering. The 4L65-E transmission shifts at higher

rpm, compared to the C5’s 4L60-E, to take advantage of the LS2’s

higher horsepower and rev range.

|